Repairing tape wire

Attention: tha authors aren&aops;t responsible for the malfunctions of the devices, which can appear as a result of using this information. Everything you do is at your own risk!

In mobile devices (smartphones, tablets, e-readers), which have been in the water, one or another flexible tape wire often breaks down. Usually, as a result of corrosion one or two conductors in the area of pin with a connector are destroyed. It happens in a few hours and usually in supplying chains through which flows a large current.

It is impossible to reestablish the metallization of the tape wire in the place, where it contacts with the connector by soldering since the conductor should be very thin, wide and flat in order to provide the contact with the knife pin of the connector.

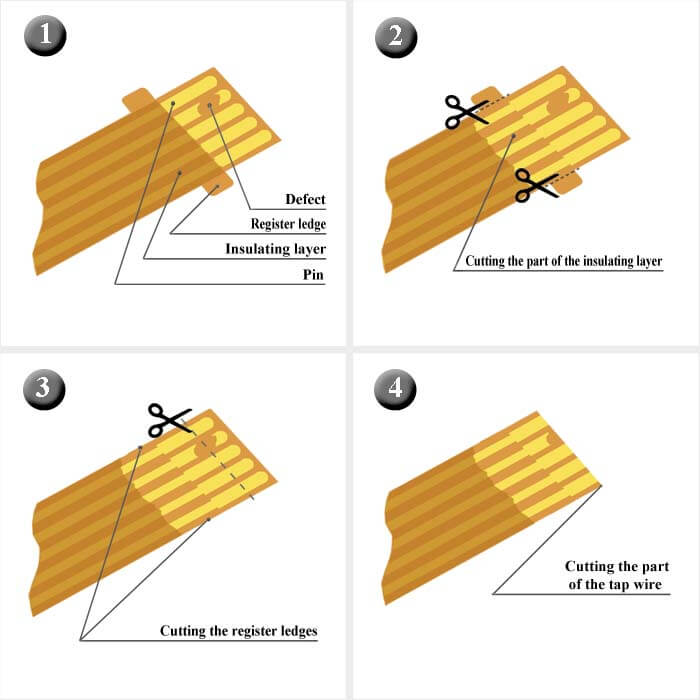

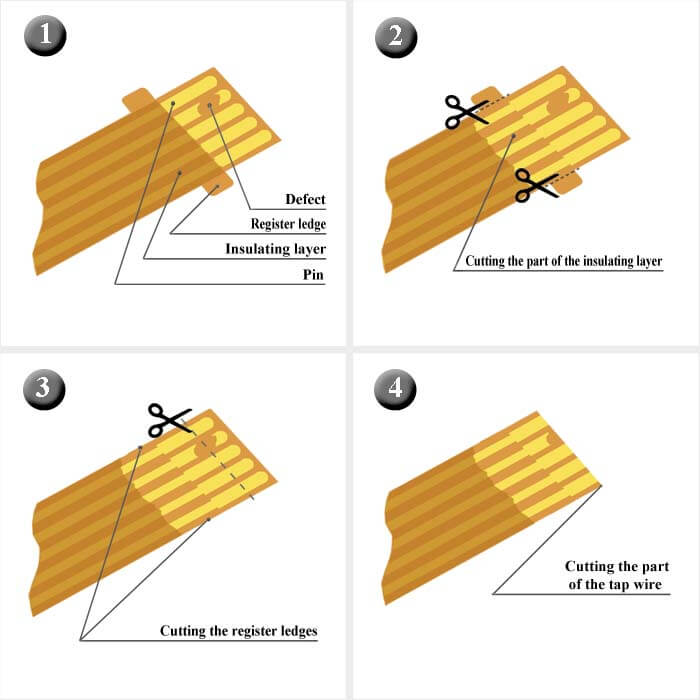

But if the tap wire has a stock of length at least 3-4 mm, then you can reestablish it this way:

- Firstly, you should carefully remove the insulating layer baring the contact area on another 2 - 3 mm (pic. 2). It is recommended to do it in two steps: firstly, you should make the area rough by the fine sandpaper and then carefully scratch the area we need with the scalpel. While doing it scalpel blade should be placed perpendicular to the tap wire in order to scrath but not cut.

- Then with the help of the scrissors you shold cut the register ledges of the tap wire (pic. 2, 3). It will make the connection of the tap wire to the connector more laborious but it will be paid off by the result of the operation.

- After that, you should very carefully cut a very thin piece of a tap wire with the scrissors from its&aops; end (pic. 3, 4), assemble the device and check it. If it is not enough then repeat this step 2 or 3 times.

As a result it is often (but not always) possible to renimate the device, which is broken and at first sight seeming irretrievably broken.

Next

What to read?

Linwood Barclay "No Time For Goodbye". On the morning she will never forget, suburban teenager Cynthia Archer awakes with a nasty hangover and a feeling she is going to have an even nastier confrontation with her mom and dad. But when she leaves her bedroom, she discovers the house is empty, with no sign of her parents or younger brother Todd. In the blink of an eye, without any explanation, her family has simply disappeared. Twenty-five years later Cynthia is still haunted by unanswered questions...

What to read?

Gregory David Roberts "Shantaram". A novel of high adventure, great storytelling and moral purpose, based on an extraordinary true story of eight years in the Bombay underworld.

'In the early 80s, Gregory David Roberts, an armed robber and heroin addict, escaped from an Australian prison to India, where he lived in a Bombay slum. There, he established a free health clinic and also joined the mafia, working as a money launderer, forger and street soldier. He found time to learn Hindi and Marathi, fall in love, and spend time being worked over in an Indian jail. Then, in case anyone thought he was slacking, he acted in Bollywood and fought with the Mujahedeen in Afghanistan...

Stephen King "11.22.63". WHAT IF you could go back in time and change the course of history? WHAT IF the watershed moment you could change was the JFK assassination? 11.22.63, the date that Kennedy was shot - unless... King takes his protagonist Jake Epping, a high school English teacher from Lisbon Falls, Maine, 2011, on a fascinating journey back to 1958 - from a world of mobile phones and iPods to a new world of Elvis and JFK, of Plymouth Fury cars and Lindy Hopping, of a troubled loner named Lee Harvey Oswald and a beautiful high school librarian named Sadie Dunhill, who becomes the love of Jake's life - a life that transgresses all the normal rules of time.

To find these books, check out the "e-library".